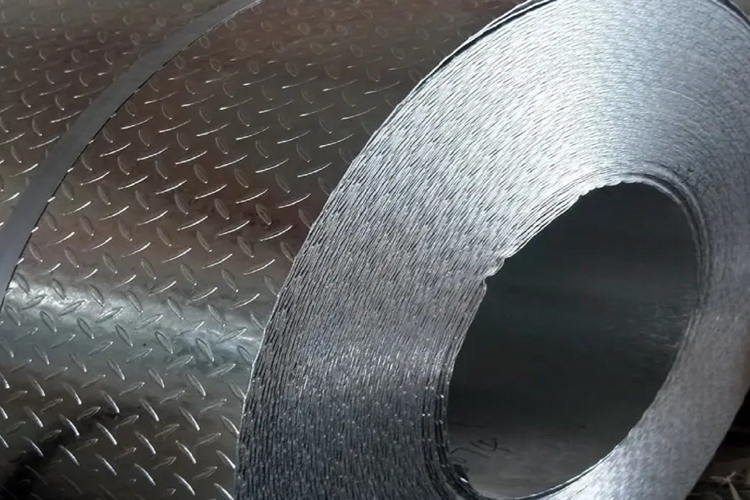

The key features of MS chequered sheets and coils include:

- Checkered Pattern: MS chequered sheets and coils have a raised pattern on their surface, typically in the form of a series of diamonds, squares, or other shapes. This pattern provides enhanced traction and slip resistance, making them suitable for flooring, walkways, stair treads, and other applications where a non-slip surface is required.

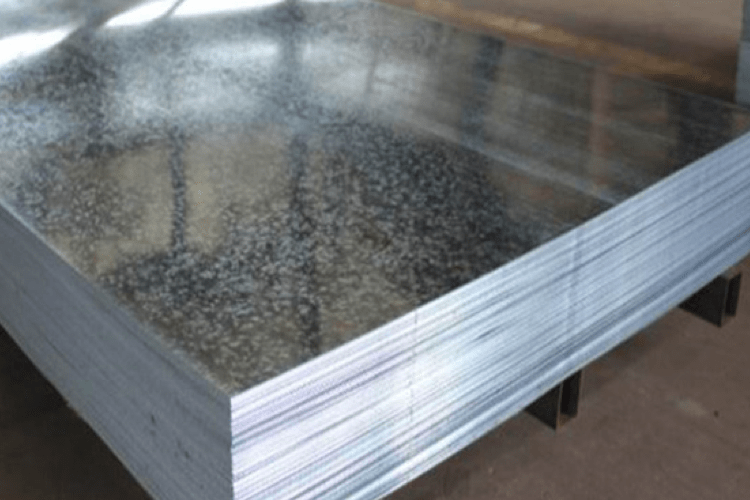

- Strength and Durability: Mild steel is known for its durability and strength, making these sheets and coils suitable for structural and load-bearing purposes.

- Corrosion Resistance: While mild steel is susceptible to corrosion, MS chequered sheets and coils can be treated with various coatings or finishes to enhance their resistance to rust and corrosion.

- Easy to Fabricate: Mild steel is relatively easy to cut, weld, and shape, which makes it a versatile material for various fabrication processes.

Applications of MS chequered sheets and coils include:

- Flooring: They are commonly used as flooring materials in industrial facilities, commercial buildings, and vehicles to prevent slipping.

- Stair Treads: MS chequered sheets are often used to cover staircases and provide a safe walking surface.

- Ramps and Walkways: They are used in places where people or vehicles need to move up or down slopes or walkways.

- Transportation: In the transportation industry, they can be used in the construction of trailers, truck beds, and other load-bearing components.

- Decorative Applications: MS chequered sheets are sometimes used in architectural and decorative applications, providing a unique aesthetic with their textured surface.

- Industrial Equipment: They can be employed in the manufacturing of machinery, platforms, and other equipment requiring a durable and non-slip surface.

- Marine and Offshore: MS chequered sheets are used in marine and offshore applications due to their anti-slip properties and corrosion resistance.

When selecting MS chequered sheets and coils, consider factors such as the size and thickness of the sheets, the type of pattern, and any specific coating or finish required for the intended application. Additionally, it’s essential to follow proper maintenance procedures to ensure the longevity and performance of these materials, particularly in environments where corrosion is a concern.