LTS Cutting & Grinding Disc Range

LTS Extra Thin Straight Cutting Disc for Metal & Stainless Steel

The LTS Extra Thin Straight Cutting Disc is a specific type of cutting disc designed for cutting both metal and stainless steel. These cutting discs

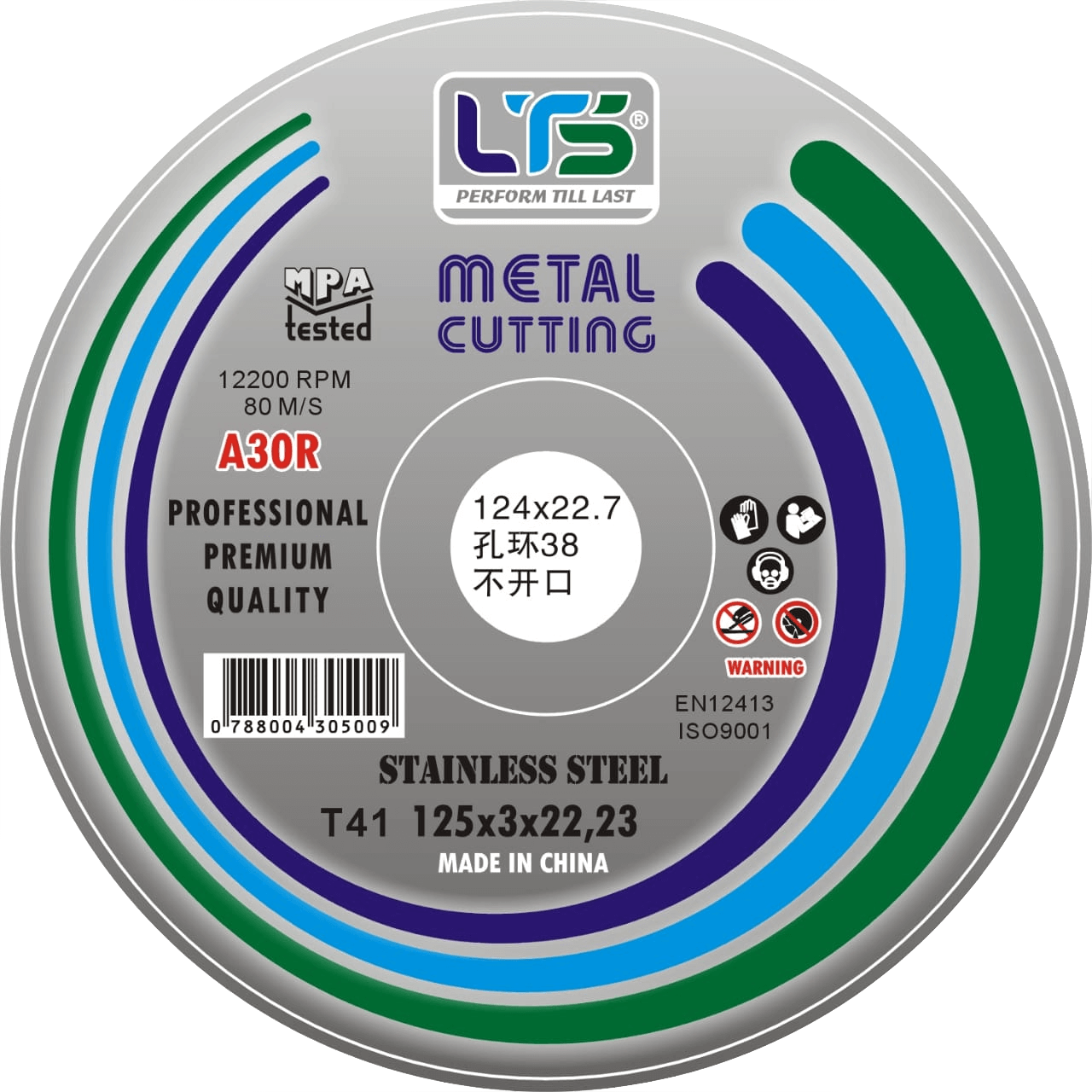

LTS Cutting Disc for Metal & Stainless Steel

LTS Cutting discs for metal and stainless steel are abrasive tools designed for cutting through various types of metal, including steel and stainless steel. These

LTS Depressed Centre Grinding Disc for Metal & Stainless Steel

LTS Depressed Centre Grinding Discs are abrasive tools designed for grinding and material removal on metal and stainless steel surfaces. They are called “depressed center”

LTS Flap / Buffing Disc for Wel & Rust Remover

LTS Flap or Buffing Discs for Welding and Rust Removal are abrasive tools designed for cleaning, smoothing, and removing welds and rust from metal surfaces.

LTS Diamond Tile Super Thin Cutting Disc

LTS Diamond Tile Super Thin Cutting Discs are specialized cutting discs designed for precise cutting of ceramic tiles, porcelain tiles, and other similar materials. These

LTS Diamond Stone / Marble Super Thin Cutting Disc

LTS Diamond Stone/Marble Super Thin Cutting Discs are specialized cutting discs designed for precise and clean cutting of stone, marble, and other hard, natural stone